This procedurally created collection explores multi-material Polyjet printing through voxel control. The resulting collection of spatially controlled composite objects investigate parametric and volumetric modelling, and an explorative approach to material mapping.

Design Process

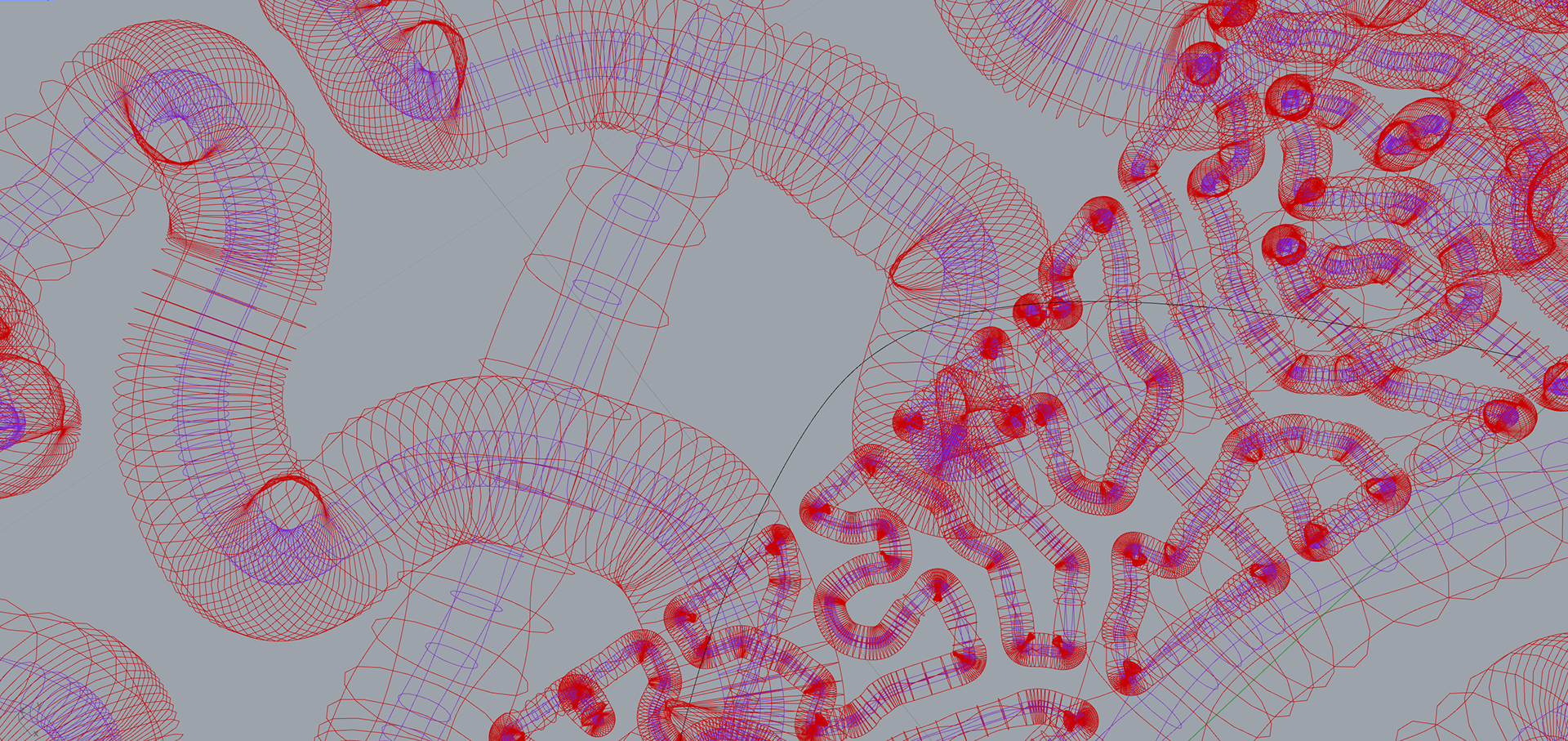

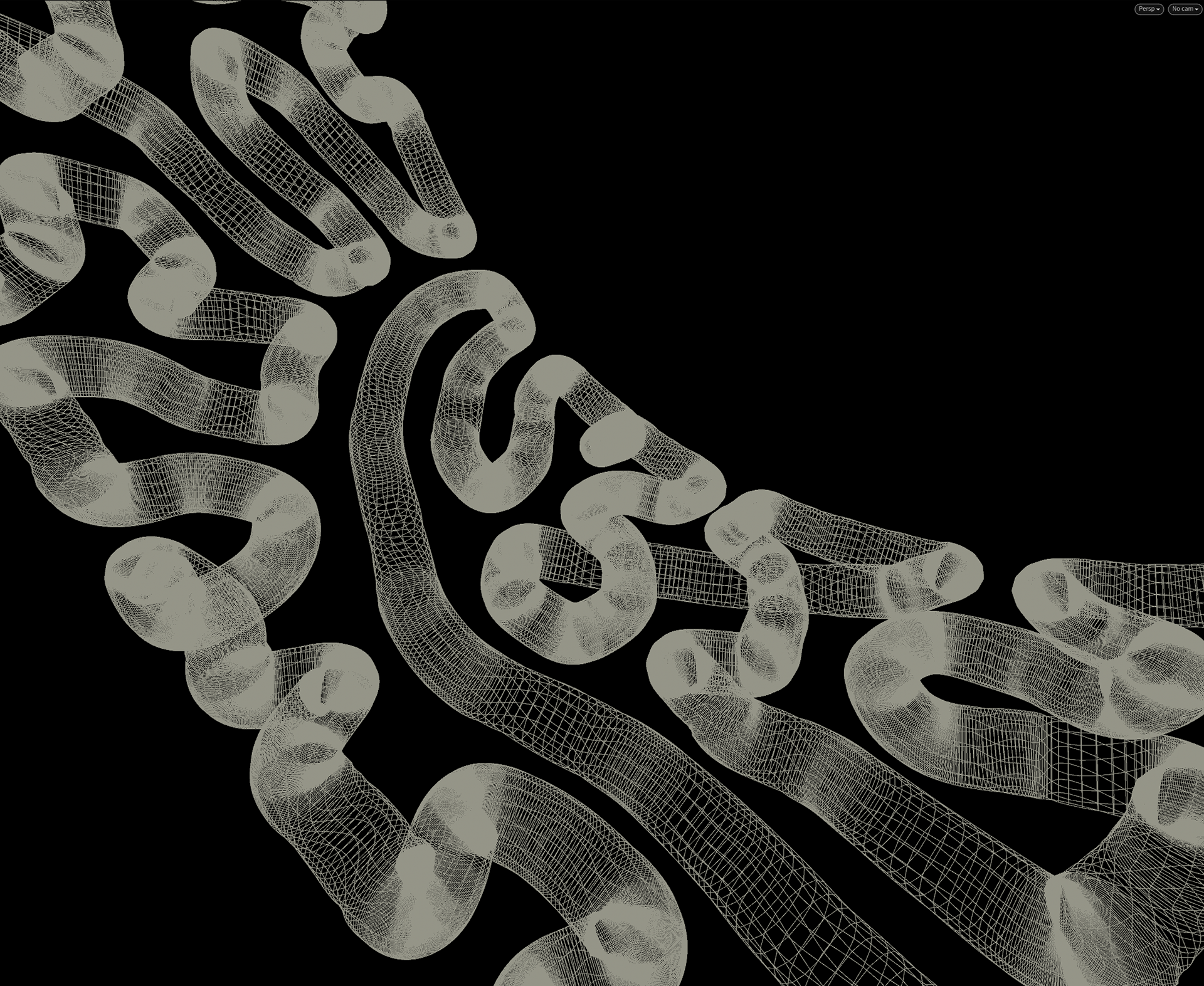

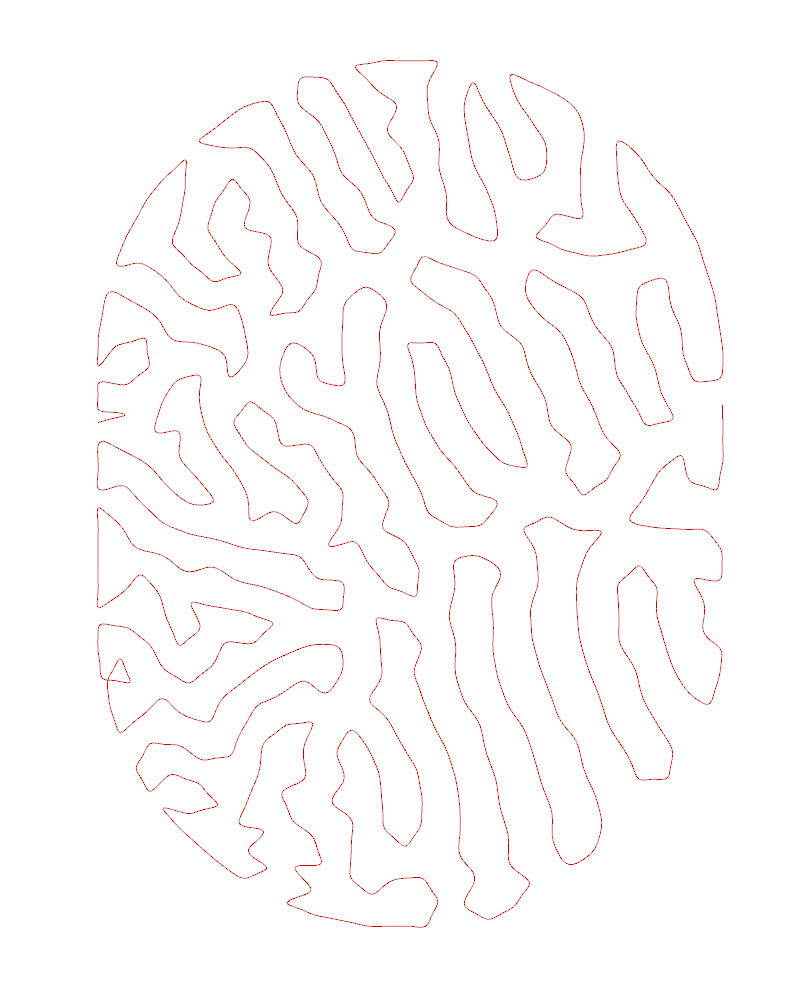

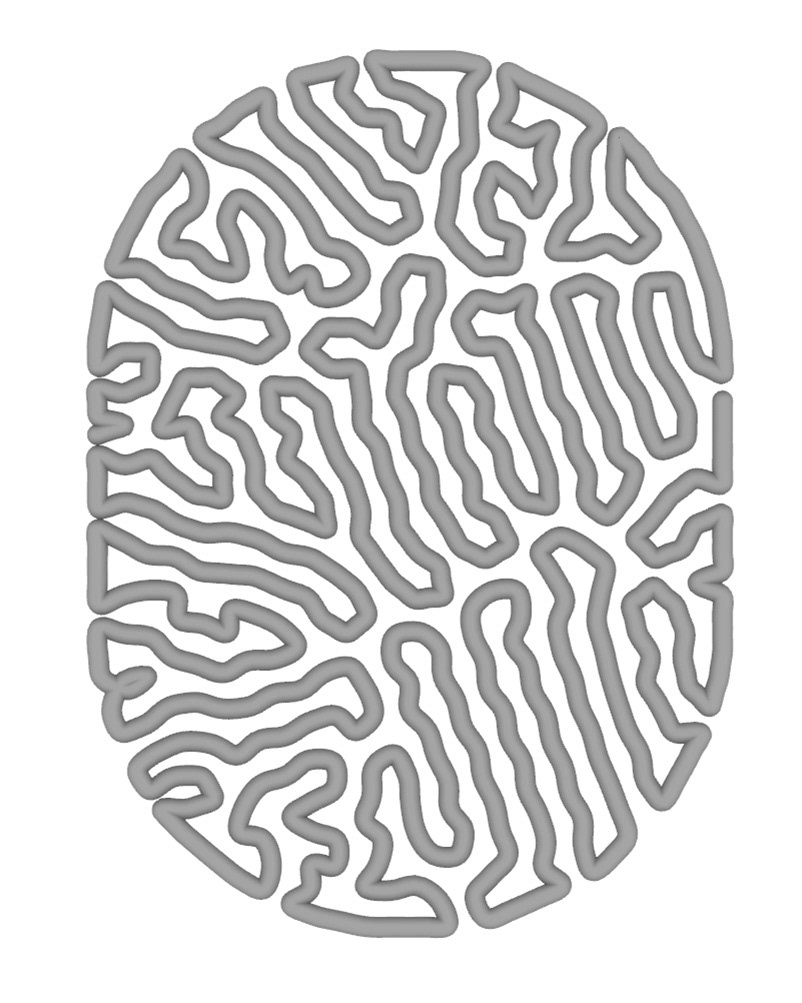

3D geometry is parametrically generated using the Rhino plug-in Grasshopper. The physics simulation plug-in ‘Kangaroo’ is used to simulate collisions between line segments, resulting in growth-like structures.

Using Houdini, this is converted into a ‘VDB’ volume, and smoothed. Colour data is added in the form of volumetric primitives, and a gradient blending effect is explored. A sequence of slice files are generated from this, describing the generated prints at a layer-by-layer, voxel-by-voxel level.

Sample prints explore different densities of input geometry, CMYK material combinations, and methods of material mapping.

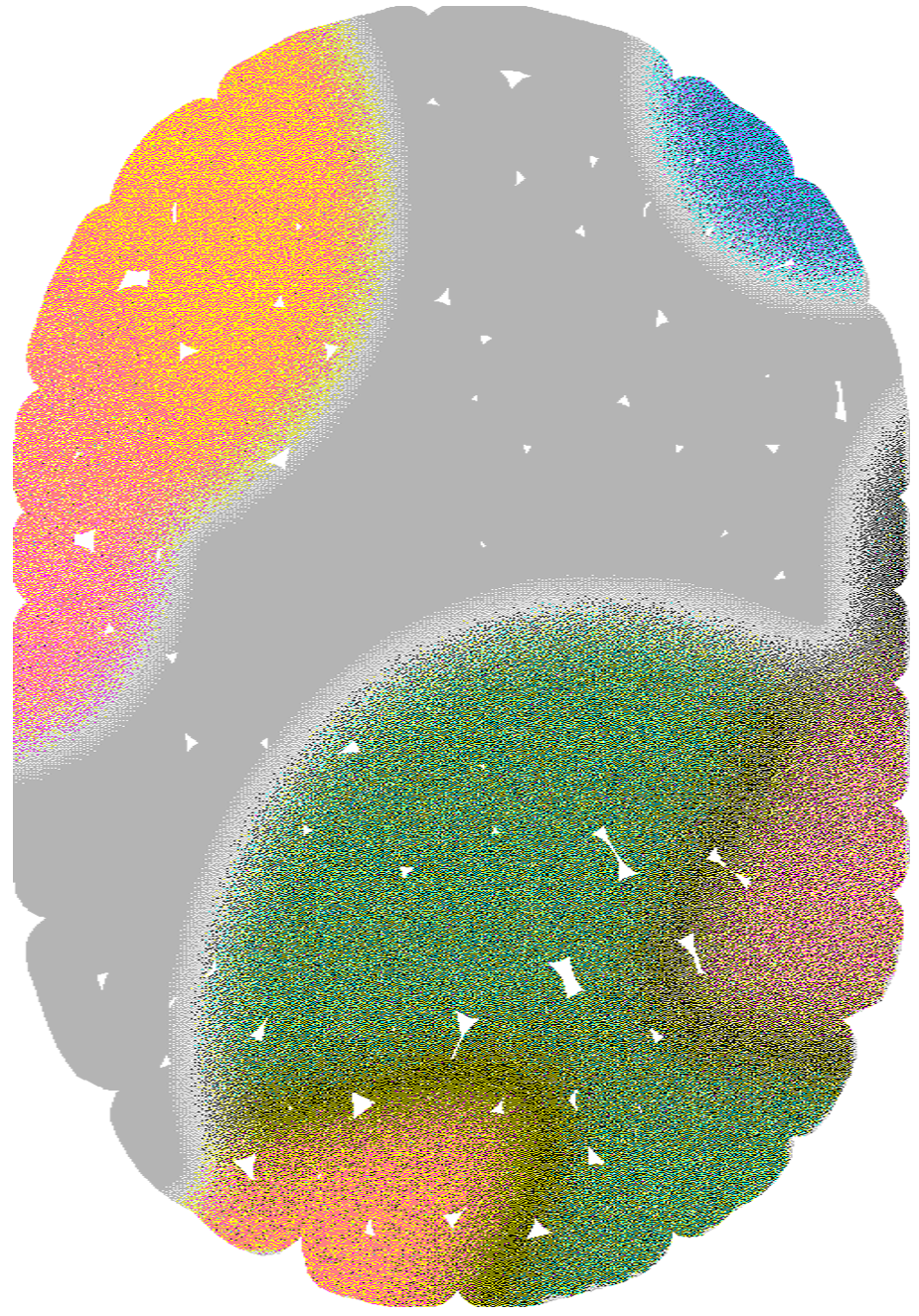

Sample Print A

This first sample shows how the digital colour blending translates into a physical print. Due to the black resin ink being more opaque than the other colours, the resulting print features very dark colours. While the outward gradient displays as white in the slice files, it printed as yellow. This is attributed to incorrect material mapping.

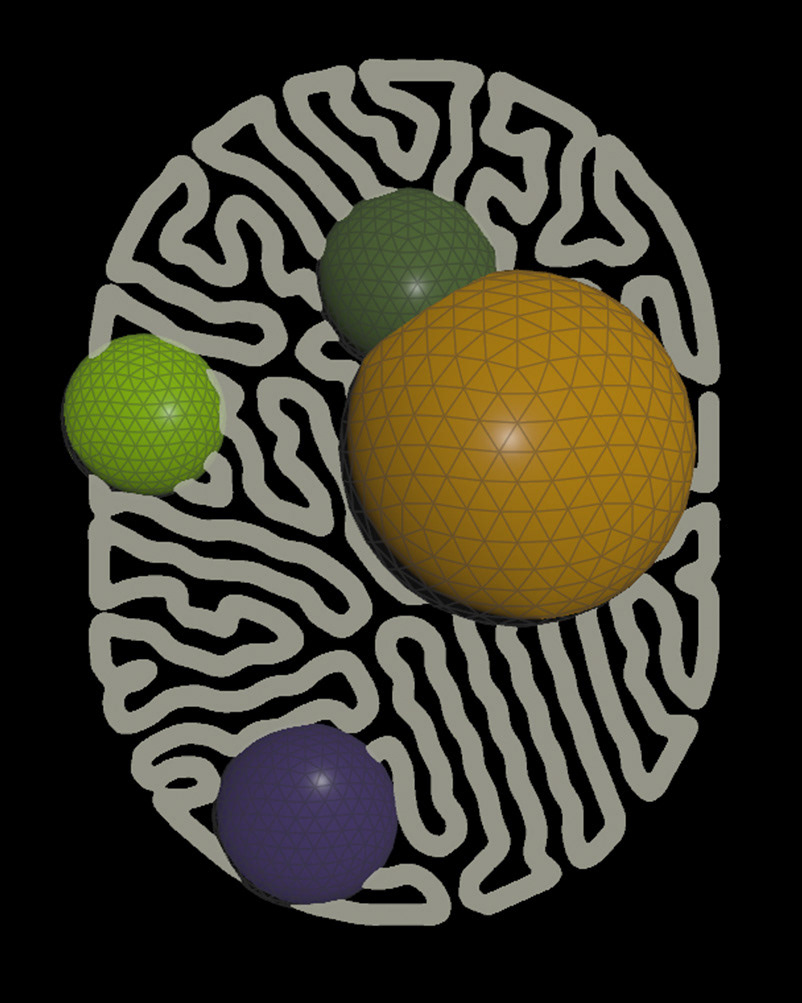

Sample Print B

Here, the input geometry is less dense, resulting in a more flexible structure. Colours correspond more closely to the visual qualities of the slice files.

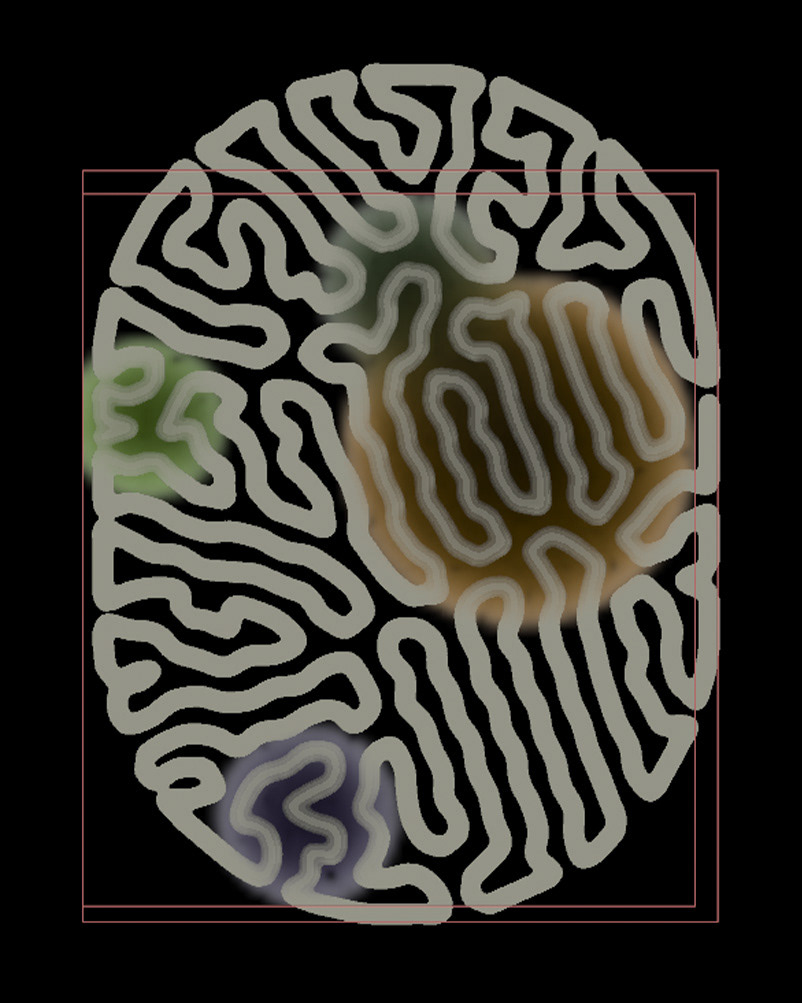

Sample Print C

This sample was created by applying the cyan colour in the digital file to correspond with the flexible Agilus material. This resulted in a functional material gradient, achieving site-specific properties within the print.

Design Outcomes

Reflection

This project improved my understanding of Houdini and the process of converting different geometries into voxel printing files.

The potential impact of multi material 3D printing with control at droplet level is immense. Particularly the functional gradient material aspect has interesting use prospects that go beyond the visual.

Further exploration could look at more specific applications, further tailoring of geometric and material properties, and having more meaningful input data.