This master's thesis focuses on the design and application of auxetic materials—a form of architected cellular lattice structure. These behave the opposite to conventional materials by expanding under tension and contracting under compression. Through this, auxetics display enhanced energy absorption, vibration damping, and localised shape conformability.

The Why

Cycling offers major benefits for health, and the environment. Making cycling accessible to more people involves addressing the main barriers that prevent people from feeling comfortable and confident on their bike. One major barrier is the discomforts many people associate with their saddle.

As an essential point of contact between user and bicycle, a saddle seeks to limit and distribute pressure placed on the sensitive parts of a rider’s anatomy. Currently, saddles come in different shapes and sizes in an attempt to accommodate the variations in pelvic anatomies. This is to reduce the discomforts of an ill-fitting saddle, such as pain, numbness and chafing. However, the anatomic differences of riders go beyond sit bone width, and include variations of pubic arch, tilt, and soft tissue.

There’s no easy one-size-fits-all solution, so the trial and error process of finding a comfortable saddle is long, expensive, and often painful. Therefore, bespoke saddles, tailored to each rider, represent the next stage in the evolution of bike seats.

Research Question

How can 3D voxel printed auxetic materials, that exhibit tailorable material qualities, be used for the customisation of sporting products?

The Design

By using an auxetic saddle structure, the saddle material becomes denser under compression and flows towards the pressure points, thereby increasing structural support. The auxetic material design also enables the saddle’s padding to dynamically conform to the complex curvatures of the human body.

Pressure mapping highlights asymmetrical pressure distributions, which affect the biomechanical efficiency and comfort of cyclists. These insights are implemented into a data-driven material modelling process. By using pressure data to drive the auxetic saddle structure and material, each cyclist's unique anatomy is factored in from the beginning of the design process.

Design Process

Auxetic Mechanism Research

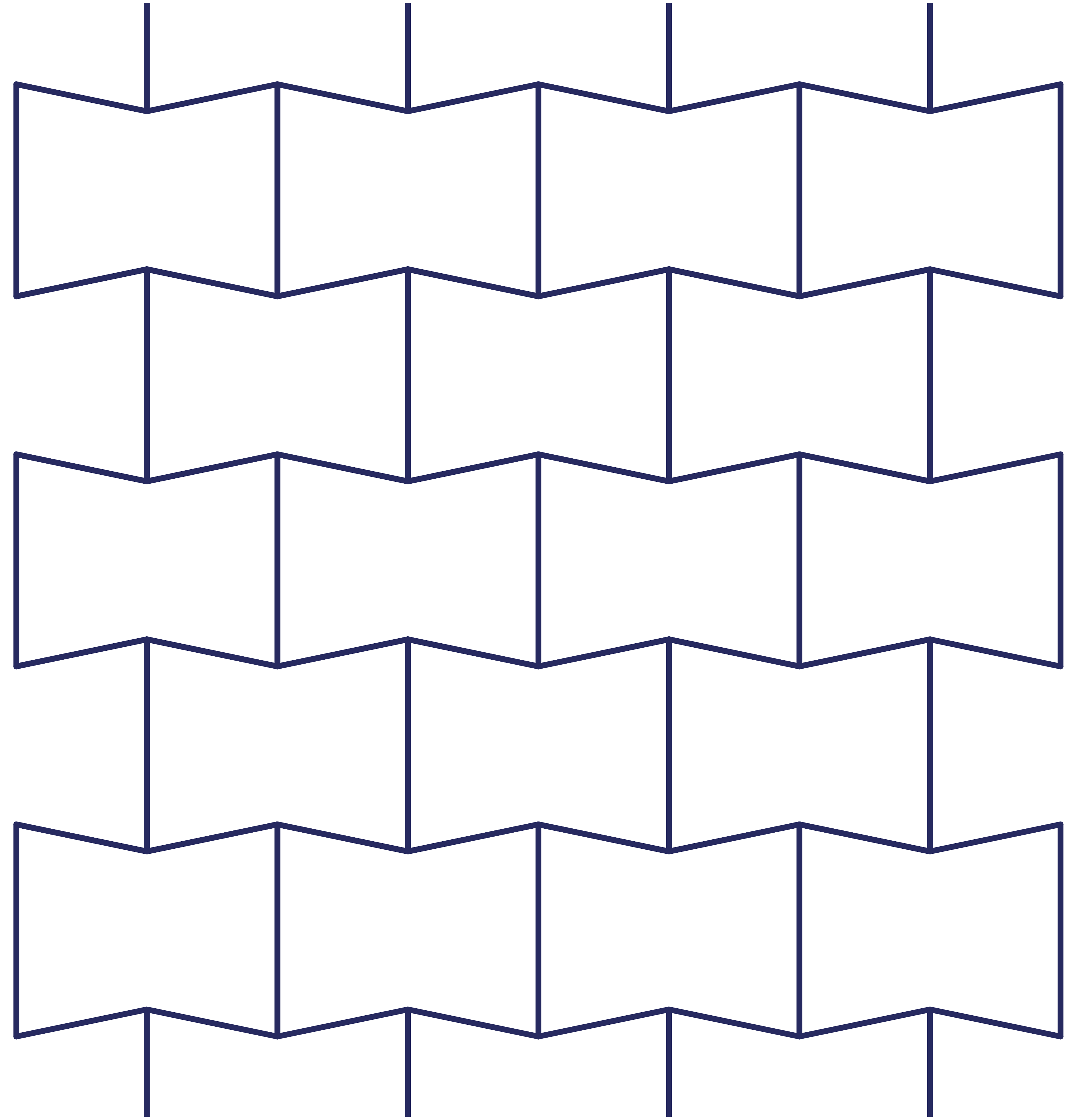

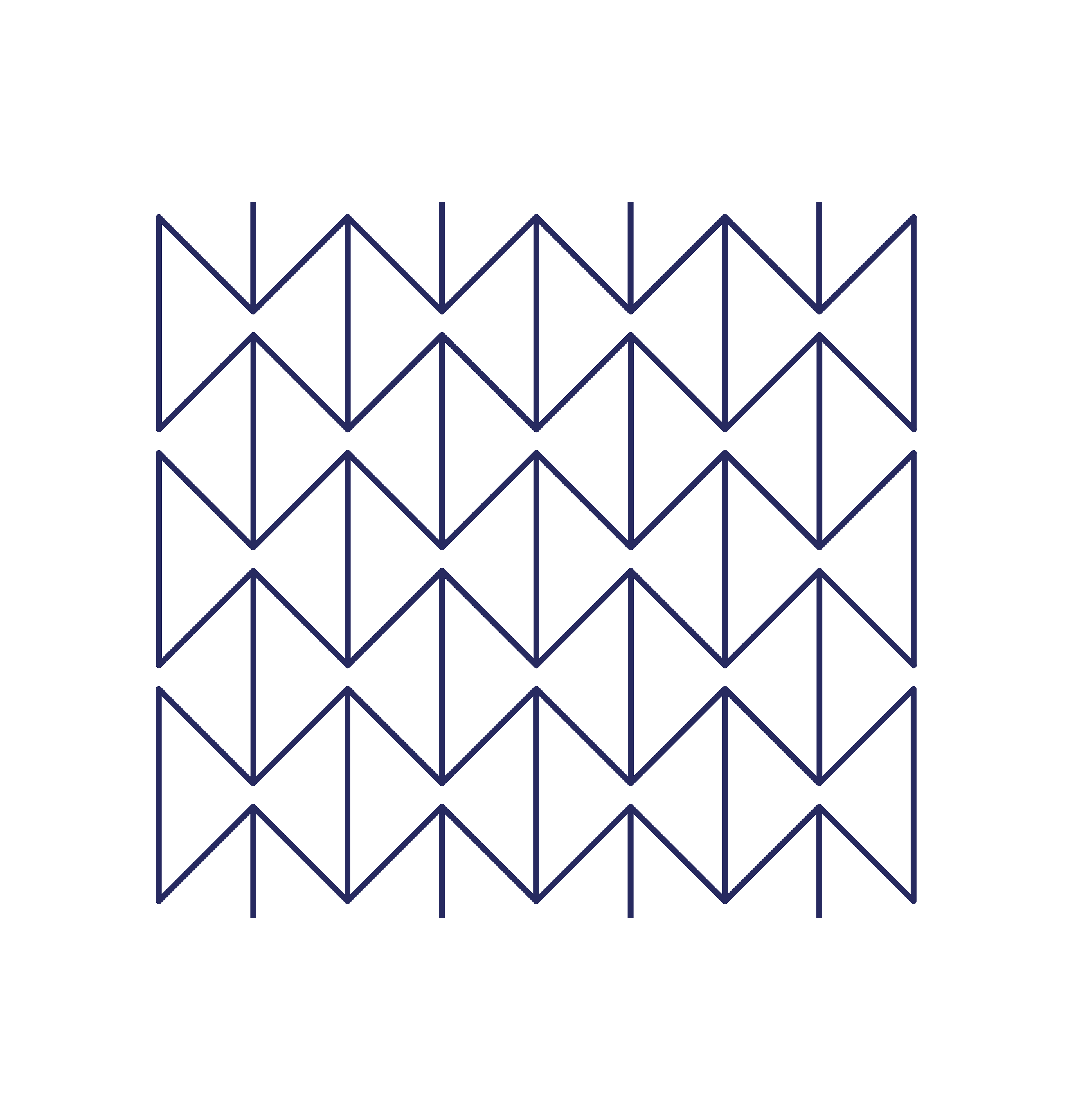

Different mechanisms that allow for auxetic deformation were examined through a literature review, and digital and physical prototyping. As the negative Poisson's ratio is achieved through an instability that occurs when a force is applied, the research sought to find a mechanism which is compatible with the properties of 3D printed photopolymers. The structure at the focus of this research was therefore the re-entrant honeycomb design, which features hexagonal cells with inward pointing corners. These cells expand under tension, and becomes denser under compression, shrinking perpendicular to the applied force.

3D Printing

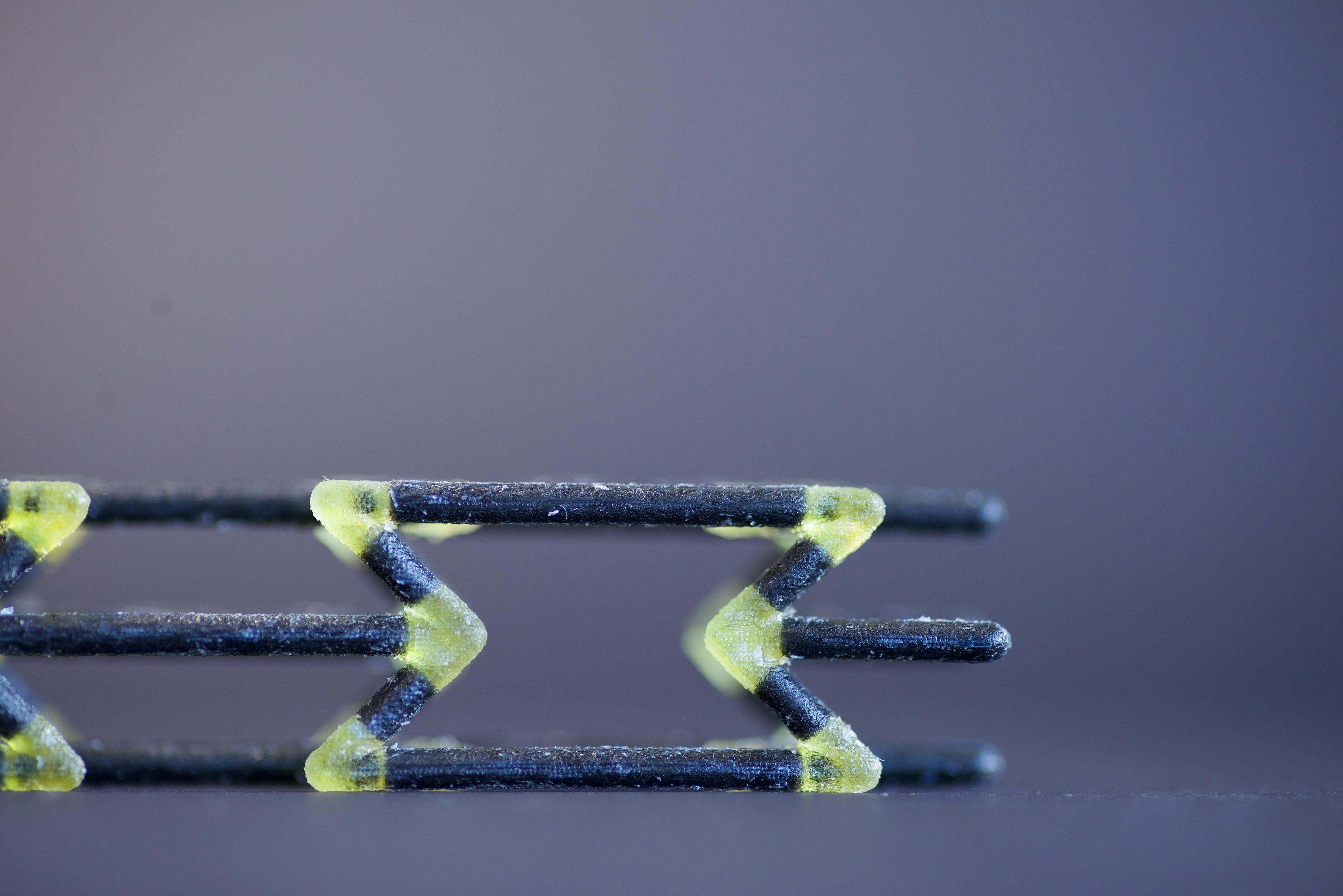

Through multi material 3D printing, the simultaneous deposition of rigid and flexible material is possible. This acts as an enabling technology for the manufacture of auxetic materials. This research focused on a cellular design that utilises flexible material in the hinge area and rigid material for struts possible. The resulting multi material auxetic not only avoids buckling problems but offers new possibilities in tailorability by increasing the ability to control the mechanical behaviours of the designed material.

Voxel-level Material Control

A voxel is a three dimensional pixel and refers to the smallest controllable unit. Voxel printing is a 3D printing process which uses pixels as volumetric representations of material, allowing for control of material allocation of every deposited sub-millimetre droplet. A voxel printing file is created from a stack of bitmap images that are compiled, each image representing a single layer of a 3D printed form, and each pixel represents a droplet.

This microscale control of multi materiality increases the design freedoms and enables digitally tailored material gradients, which relate to controllable and gradual changes in material performance. By refining material design to the smallest definable unit, and utilising the print resolution of the Stratasys J850 3D printer, this research harnesses the control gained through the capabilities of volumetric material design.

Multi-materiality is described by droplets of material, which are deposited based on a stack of bitmap images, where one pixel corresponds to a droplet of material.

Procedural Modelling & Prototyping

To produce parametrically controlled material samples, this project included the development and refinement of a procedural workflow, used to enhance the tailorability of auxetic materials and the gradients within these structures.

Prototypes are produced using FDM printing as well as material jetting, and evaluated using experimental mechanical testing methods, including a uniaxial compression rig and FEA analysis. Shore hardness measurements were used to quantify the effects of changing material distribution in the different areas of the 3D printed structures.

Pressure Mapping

Through a sensorised mat, a rider’s pressure distribution is analysed, and sit bone distance as well as any additional high pressure zones and asymmetries can be identified. This data is used in the saddle’s material design to create functional zones that are optimised for the individual rider.

Softer material is used for areas of high pressure, to minimise swelling of soft tissue. Sit bones carry most of a rider’s weight. These zones features stiffer material to provide structural support.

Design for Manufacture

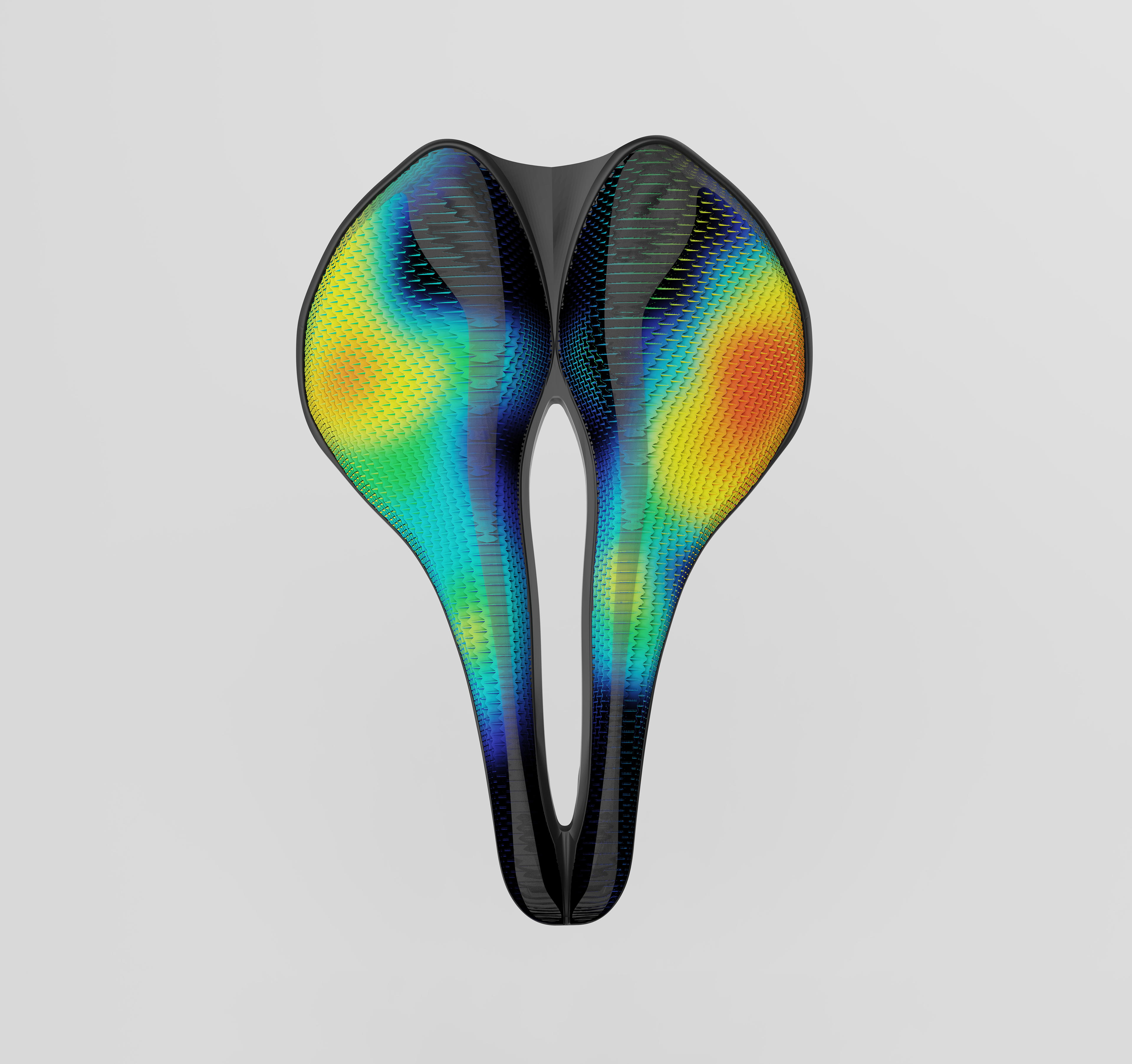

The saddle padding is 3D printed using material jetting technology, allowing for controlled gradients between rigid and flexible material. The lattice orientation minimises the use of support material, making a wall thickness of less than 0.4 mm possible.

Final Prototype

The variations of pressure zones are reflected in the varying stiffness of the saddle material. This combination of different zones helps to redistribute pressure onto the rider's sit bones. The material is stiffest by the contact points of the sit bones, to offer structural support. The rider’s most pressure-sensitive areas rest on the front half of the saddle. These areas of the saddle are softer, and highlighted in pink. The nose of the saddle is also soft, creating a cushioning zone when the rider switches their position on the bike, for example when leaning forwards going uphill.

The saddle features a pressure relief cut out, which is also personalised to the rider's anatomy. This helps to minimise pressure on the most sensitive central areas.

The stiffness gradients between zones are made possible through material jetting 3D printing, which enables the controlled deposition of flexible and rigid photopolymers. Voxel-level control of these micromillimeter droplets creates a seamless transition between soft and hard materials, resulting in functional material gradients that reflect the ergonomic needs of the rider.

By combining 3D printed material gradients with customised material design based on an individual's pressure distribution, the saddle exemplifies product design that embraces anatomical differences, aiming to make cycling comfortable.

Handlebar Grips

A set of grips was also developed as part of this project. These feature softer material in the palm area, to provide cushioning, and stiffer material in the gripping area, providing stability for the fingers when gripping. The material distribution of flexible to rigid materials uses the volumetric material design process, and features gradients that would not be possible through other methods.

This work is the output from a research portfolio for a Master of Design Innovation, completed at Victoria University of Wellington, in July of 2024.

For more information on this project, please contact the author.